UAV Payload for Target Detection and Air Quality

The UAV Payload project, or as we liked to call it, "Operation Sky-Sampler," is an advanced unmanned aerial vehicle (UAV) payload designed for three main tasks: target detection, soil sampling, and air quality monitoring in the kind of places that make GPS cry for help (a.k.a. GPS-denied areas). This project used some serious systems engineering magic to make it all work all in the space of 6 months. In this blog, we’ll take a look at the core components of the project, from management strategies to the design and integration of each subsystem – and we promise to keep it more engaging than your average assessment report.

Project Management

Managing the UAVPayloadTAQ project was all about breaking it down into bite-sized pieces. We had clearly defined phases, distinct milestones, and more checklists than a wedding planner. We used a Work Breakdown Structure (WBS) to split the project into manageable tasks like planning, subsystem development, integration, and testing. GitHub was our trusty sidekick for version control, keeping everyone in sync and avoiding the dreaded "but I thought you changed that code" conversation.

Our guiding star was the Project Management Plan (PMP), which laid out detailed timelines, resource allocation, and budgets for mass, power, and data. Think of it like an IKEA manual, but for a flying robot that smells the air and digs up dirt. We kept everything aligned with our high-level objectives, thanks to the Requirements Traceability Matrix (RTM). Basically, if it wasn’t in the matrix, it wasn’t in the project – no rogue additions allowed.

Air Quality

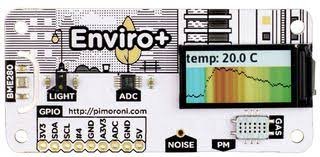

The air quality monitoring subsystem was designed to snoop around the atmosphere, collecting data on pollutants and environmental metrics. Our trusty Raspberry Pi 5 was the brain of this operation, interfacing with the Pimoroni Enviro+ Sensor Board and a bunch of other sensors – including a MiCS-6814 gas sensor, a weather sensor, and a light sensor. Essentially, it was like strapping a weather station and a chemistry lab to a drone.

The architecture focused on reliability and responsiveness, featuring a cute little LCD that showed real-time air quality data. If you wanted more data crunching, it could also send everything to a web server. And yes, if you were curious, the Raspberry Pi is also capable of playing retro games – but we managed to resist the temptation (mostly).

Sampling Tube and Enclosure

The Sampling Tube and Enclosure subsystem was our dirt-digging specialist. This bit of kit was responsible for grabbing soil samples – and we went through quite a few design iterations to make sure the drone didn’t wobble around like a shopping trolley with a broken wheel. Eventually, we ended up with a lightweight drill mechanism powered by a high-torque motor, perfectly designed to plunge into the earth and grab soil samples like a really determined mole.

We made sure the enclosure was as aerodynamic as possible, which was a polite way of saying we spent way too much time trying to make it look less like a clunky lunchbox. After testing several versions, we landed on an enclosure that both minimised drag and kept our precious samples safe.

Target Detection and Image Processing

Target detection and image processing was the subsystem that brought the "look" in "look, a flying robot!" This component used the OAK-D Lite camera alongside our good friend, the Raspberry Pi 5, to conduct object recognition and target detection. Think OpenCV libraries and YOLO-based detection models, all working together to find valves, gauges, and specific markers – because what’s a good UAV without a little spy drama?

We went through various design iterations to improve detection in dodgy lighting conditions and to boost accuracy with a heap of augmented data. The real-time feedback from this subsystem made our UAV feel a little smarter, and if it could talk, it probably would have said, "I’m ready for my mission, commander."

Web Visualisation and User Interface

To make all this data and control less of a guessing game, we implemented a web visualisation and user interface subsystem. This was like our mission control, built on the Flask framework, which included real-time streaming with WebSockets and an SQL database to store all that juicy data. The front-end, built with React, was basically a fancy dashboard that allowed users to view sensor readings, check out air quality metrics, and watch our little spy cam do its thing.

The web interface was designed to be so intuitive that even a sleep-deprived team member could operate it at 2 AM. It had pages for streaming video, visualising sensor data over time, and monitoring target detection results – all helping our operator to make informed decisions while our drone did its thing in the skies.

The UAVPayloadTAQ project was a wild ride, integrating different technologies into one cohesive flying payload that could operate autonomously in some pretty tough environments. With attention to subsystem design and top-notch project management, we made a UAV that didn’t just fly – it thought, sampled, and analysed, all without needing GPS hand-holding. And let’s face it, that’s pretty cool.